Tech: Mercedes to Debut F1's MGU-H in Road Cars

F1 first introduced the concept of the MGU-H in the 2014 engine regulations overhaul, when F1 turned to turbocharged V6 hybrid powerunits, after running naturally aspirated V8’s since 2006.

Out of all the newly developed areas in these complex powerunits, it’s the MGU-H that is the most criticised, with many having pushed to remove the concept from F1 due to its large expense in research and development, in a bid to get more manufacturers to join the sport.

Mercedes were the first team to fully get their heads’ around the MGU-H concept, and consequently have won every season of Formula 1 since its introduction in 2014. They have long argued that the technology will benefit the automotive industry like so many previous innovations in motorsport, and now that finally seems to have come to fruition.

Unlike in modern F1 cars, the MGU-H that Mercedes’ high performance division AMG has been developing for its road cars will not directly benefit performance through an increase in power, but rather will be used to decrease turbo lag.

Turbo lag is an issue that plagues all turbocharged engines – when you accelerate, there is always a delay for the turbo to accelerate to its revolving speed. Whilst the turbo is accelerating, it’s only the power from the engine that is running the car. When the turbocharger kicks in, there is a sudden increase in power that could exceed well over 100bhp, which poses a safety issue, especially if the driver is inexperienced. Turbo lag also impacts the overall performance of the car, delaying throttle response and therefore acceleration figures.

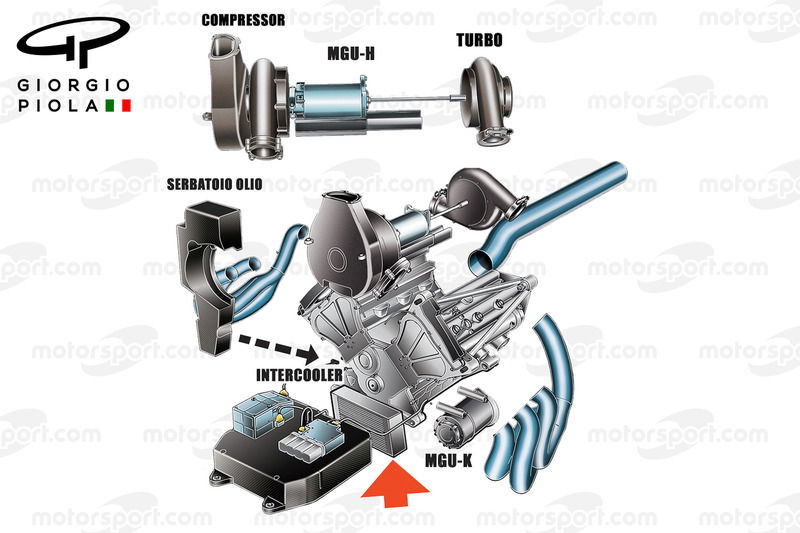

Giorgio Piola - a breakdown of the turbo-hybrid F1 powerunit

Giorgio Piola - a breakdown of the turbo-hybrid F1 powerunit

The MGU-H that AMG will use is understood to be applied in a new ‘electric exhaust gas turbocharger’, which will be included to all new production AMG models.

Just how far electric motor technology has come along is also shown in this new feature – an electric motor that is just 4cm wide will be integrated onto the charger shaft, in between the compressor wheel on the fresh air side and the turbine wheel on the exhaust side.

With the turbocharger running at around 170,000rpm, the compressor wheel will be driven by the motor before the exhaust gas is introduced. Normally, the exhaust gas would be what drives the compressor wheel.

Overall, this will improve the throttle response and allow for higher torque values at lower engine speeds, giving an overall better driving experience.

A statement from AMG Chairman of the Board of Management (and new Aston Martin CEO) Tobias Moers says: "We have clearly defined our goals for an electrified future.

"In order to reach them, we are relying on discrete and highly innovative components as well as assemblies.

"With this move we are strategically supplementing our modular technology and tailoring it to our performance requirements. In a first step this includes the electrified turbocharger - an example of the transfer of Formula 1 technology to the road, something with which we will take turbocharged combustion engines to a previously unattainable level of agility."